- HOME

- RESEARCH

- Research Units

- Advanced Structural Materials

RESEARCH

Advanced Structural Materials

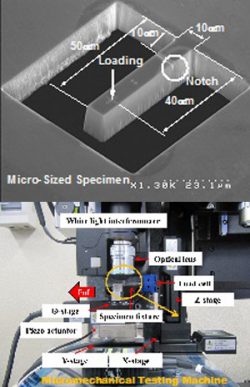

The mechanical properties of materials are dominated by their microstructures such as grain size, precipitates, phase boundary, grain boundary, etc. In our research group, we aim to clarify the mechanical properties at microscopic level, including tensile properties, fracture and fatigue properties, using the micromechanical testing technology that we have developed. Furthermore, in conjunction with crystal plasticity finite element simulation, we aim to predict the mechanical properties of bulk materials based on those at microscopic scale. The results obtained in this research will contribute for developing toughening design of advanced materials.

Unit members

-

Unit CoordinatorYoji MINE

Unit CoordinatorYoji MINEProfessor

Faculty of Advanced Science and Technology, Kumamoto UniversityJapan -

Kazuki TAKASHIMA

Kazuki TAKASHIMADistinguished Professor

International Research Organization for Advanced Science and Technology (IROAST), Kumamoto UniversityJapan -

Kwangsik KWAK

Kwangsik KWAKAssistant Professor

Faculty of Advanced Science and Technology, Kumamoto UniversityJapan -

Yufeng ZHENG Website

Yufeng ZHENG WebsiteProfessor

School of Materials Science and Engineering, Peking University

*IROAST Distinguished ProfessorChina -

Paul BOWEN Website

Paul BOWEN WebsiteFeeney Professor of Metallurgy

School of Metallurgy and Materials, University of Birmingham

*IROAST Visiting ProfessorUK -

Yu-Lung CHIU

Yu-Lung CHIUProfessor

School of Metallurgy and Materials, University of BirminghamUK -

Hiroto KITAGUCHI

Hiroto KITAGUCHISenior Research Fellow

School of Metallurgy and Materials, University of BirminghamUK -

Martin DIENWIEBEL Website

Martin DIENWIEBEL WebsiteHeisenberg-Professor

The Institute for Applied Materials - Reliability and Microstructure (IAM-ZM), Karlsruhe Institute for Technology (KIT)

*IROAST Visiting ProfessorGermany

Achievements

Publications

K. Kwak, T. Mayama, Y. Mine, K. Ohishi, T. Ueno, K. Takashima, Multiscale mechanical characterization of 601 nickel-based superalloy fabricated using wire-arc additive manufacturing, Mater. Sci. Eng. A 836 (2022) 142734.

D. Bayoumy, K. Kwak, T. Boll, S. Dietrich, D. Schliephake, J. Huang, J. Yi, K. Takashima, X. Wu, Y. Zhu, A. Huang, Origin of non-uniform plasticity in a high-strength Al-Mn-Sc based alloy produced by laser powder bed fusion, J. Mater. Sci. Technol. 103 (2022) 121–133.

S. Ueki, K. Koga, Y. Mine, K. Takashima, Crystallographic characterisation of hydrogen-induced twin boundary separation in type 304 stainless steel using micro-tensile testing, Tetsu-to-Hagané 108 (2022) 97–106 (in Japanese).

K. Takagi, E. Hashamova, M. Dienwiebel, Y. Mine, K. Takashima, Correlation of wear behaviour and microstructural evolution in Mg-Zn-Y alloys with long-period stacking ordered phase, Wear 482–483 (2021) 203983.

S. Ueki, Y. Mine, X. Lu, Y.L. Chiu, P. Bowen, K. Takashima, Effect of geometric lath orientation on fatigue crack propagation via out-of-plane dislocation glide in martensitic steel, Scr. Mater. 203 (2021) 114045.

A. Matsushita, Y. Mine, K. Takashima, Enhanced resistance to fatigue crack propagation in metastable austenitic stainless steel by nanotwin bundles, Scr. Mater. 201 (2021) 113976.

A. Matsushita, S. Ueki, Y. Mine, K. Takashima, Comparative study of microstructure-sensitive fatigue crack propagation in coarse- and fine-grained microstructures between stable and metastable austenitic stainless steels using miniature specimen, ISIJ Int. 61 (2021) 1688–1697.

Y. Shimada, K. Harada, Y. Mine, M. Yoshimura, K. Takashima, Low-temperature micro-fracture toughness testing of grain boundaries in steel, Mater. Trans. 62 (2021) 570–573.

J. Wu, S. Si, K. Takagi, T. Li, Y. Mine, K. Takashima, Y. L. Chiu: “Study of basal <a> and pyramidal <c + a> slips in Mg-Y alloys using micro-pillar compression”, Phil. Mag., 100 (2020) pp. 1454-1475.

Ueki, R. Oura, Y. Mine, K. Takashima: “Micro-mechanical characterisation of hydrogen embrittlement in nano-twinned metastable austenitic stainless steel”, Int. J. Hydrogen Energy, 45 (2020) pp. 27950-27957.

Grants

Elucidation of plastic deformation mechanism of additively manufactured Ti-6Al-4V alloys using trans-length scale mechanical characterization, KAKENHI Grant-in-Aid for Early-Career Scientists 2021-2024 (New).

Development of local strengthening of micro-mechanical components using martensitic transformation induced by focused ion beam irradiation, KAKENHI Grant-in-Aid for Challenging Exploratory Research 2021-2022 (New).

Elucidation of fatigue crack growth mechanism of martensite steels using micro-mechanical testing technique and application to fatigue strengthening design, KAKENHI Grant-in-Aid for Scientific Research (A) 2020-2024 (Continuing).

Exploration of guiding principles for toughening design of hydrogen-resistant materials using multi-scale mechanical testing, KAKENHI Grant-in-Aid for Scientific Research (B) 2019-2021 (Continuing).

Activities

- Units of World-leading Researchers

-

- Development of Nano and Supramolecular Materials

- RNA Biology

- Plant Cell and Developmental Biology

- Nano-Organics and Nano-Hybrids

- Nano-medicine and Drug Delivery System

- Nano-medicine and Theranostics

- Multiscale Modeling of Soil and Rock Materials Using X-ray CT

- Quantification of Three Dimensional Vascular Network

- MicroCT-based Quantification of Fibrosis and Vascularization in Pancreatic Tumor

- Advanced Structural Materials

- Microstructure Analysis and Grain Boundary Engineering

- Structure and Dynamics of Materials Using Quantum Beams and Data-Driven Sciences

- Hydrological Environments

- Nano-materials for Energy Applications and Environmental Protection

- Units of Young Researchers

-

- Quantitative Bioimaging

- Development of Novel Therapeutic Strategy Using Iron Targeted Upconversion Nanoparticles for Parkinson's Disease

- Deep Learning for Hydrology

- Environmental Impacts of Ionic Solutes

- Study of first-generation objects in the universe with radio telescopes

- Plant Stem Cells and Regeneration

- Development of Microbially-Aided Carbon Sequestration Technology

- Advanced Biomedical Evaluation System

- Bio-inspired Functional Molecular System

- Nanomaterials Processing for Medical, Cosmetic, and Environmental Applications

- Ferroelectric Photovoltaics

- Next-Generation Design of Structures