STAFF

Dr. Kazuki TAKASHIMA

Distinguished Professor

International Research Organization for Advanced Science and Technology

Email address: takashik[at]gpo.kumamoto-u.ac.jp

- Research Fields

- Fracture and Fatigue, Mechanical Properties, Materials Evaluation

Research interest

Micro-mechanical Characterization

K. Takashima

1. Development of Testing Methods for Micro-Sized Materials

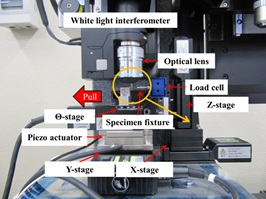

Since thin films are used as structural materials in MEMS (Micro Electro Mechanical System) devices, it is necessary to accurately measure the mechanical properties of thin films in order to improve the reliability and durability of the devices. We are developing testing methods for micron to submicron size components fabricated from thin films. The results obtained will greatly contribute to the development of MEMS devices.

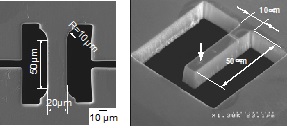

Fig. 1 Examples of micro-sized specimens for tensile, bending, fracture and fatigue tests.

Fig. 2 Micro-materials testing machine developed in our laboratory. We are measuring the deformation, fracture, and fatigue behavior of micro-sized materials using this testing machine.

2. Evaluation of Mechanical Properties of Hierarchical Microstructures in Materials

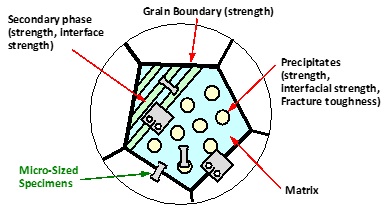

The mechanical properties of a bulk material depend on the mechanical properties of its microstructure, such as grain size and precipitates, and microstructural control improves the material properties. Therefore, investigating the mechanical properties at such a microscopic level will lead to the development of new materials with superior mechanical properties. In this research, we evaluate the mechanical properties of advanced materials, including high strength steels, Ti alloys and Mg alloys, at the microstructure level to elucidate the deformation and fracture mechanisms and to develop high-strength and high-toughness materials. This laboratory is the only one in the world that conducts such research, and the results are highly anticipated.

Fig. 3 If micro-sized specimens are prepared from micro-constituents in materials, and micromechanical testing is performed for such specimens, the mechanical properties, including grain boundary strength, fracture toughness of precipitate, interfacial strength between matrix and secondary phase, etc., can be measured. The evaluation of mechanical properties of microstructure is essential for the designing high strength material.

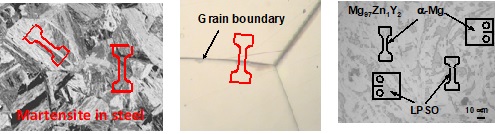

Fig.4 Preparation of micro-sized specimens from the constituents of material structure

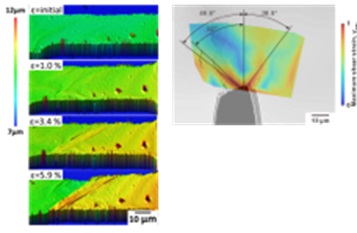

Fig. 5 Deformation behavior and strain distribution are measured to elucidate deformation and fracture mechanisms.

Achievement

Publications

- 2024

-

- Effect of Inhomogeneous Microstructure on Strength and Fracture Resistance in Sharp Edge of Japanese Swords

- Additive manufacturing of WE43 and modified AZ91D magnesium alloys using the laser engineered net shaping process

- Effects of crystallographic orientation and lamellar configuration on fatigue crack propagation in single-colony structures of Ti–6Al–4V alloy: Alternating shear crack growth vs. damage accumulation crack propagation

- 2023

- 2022

-

- Correlation between strength and hardness for substructures of lath martensite in low- and medium-carbon steels

- Comparative Study of Shear Fracture between Fe-based Amorphous and Ultrafine-grained Alloys Using Micro-tensile Testing

- Micro-mechanical characterisation of slip behaviour and precipitation strengthening in CoCrFeNiTiMo alloy additively manufactured by laser powder bed fusion

- Multiscale mechanical characterization of 601 nickel-based superalloy fabricated using wire-arc additive manufacturing

- Origin of non-uniform plasticity in a high-strength Al-Mn-Sc based alloy produced by laser powder bed fusion

- 2021

-

- Enhanced resistance to fatigue crack propagation in metastable austenitic stainless steel by nanotwin bundles

- Comparative study of microstructure-sensitive fatigue crack propagation in coarse- And fine-grained microstructures between stable and metastable austenitic stainless steels using miniature specimen

- Low-temperature micro-fracture toughness testing of grain boundaries in steel

Grants

Grant-in-Aid for Challenging Exploratory Research (The Japan Society for the Promotion of Science), “Development of local strengthening of micro-mechanical components using martensitic transformation induced by focused ion beam irradiation,” April 2021-March 2023

Grant-in-Aid for Scientific Research (A) (The Japan Society for the Promotion of Science), “Elucidation of fatigue crack growth mechanism of martensite steels using micro-mechanical testing technique and application to fatigue strengthening design,” April 2020-March 2025

Grant-in-Aid for Scientific Research (B) (The Japan Society for the Promotion of Science), “Exploration of guiding principles for toughening design of hydrogen-resistant materials using multi-scale mechanical testing,” April 2019-March 2022

- STAFF

-

- Wei XU

- Shinichiro Sawa

- Tetsuya KIDA

- Armando T. QUITAIN

- Junhua WANG

- Yoshihiro SEKINE

- Akira UEDA

- Yusuke INOMATA

- Muhammad Sohail AHMAD

- Jonas Karl N. AGUTAYA

- Nobleson KUNJAPPY

- Prafulla Bahadur MALLA

- Mohammad Atiqur RAHMAN

- Reetu Rani

- Kei TODA

- Tomoyasu MANI

- Agus Pulung SASMITO

- Tung Thanh TRAN

- Dario ZAPPA

- Daniel P. ZITTERBART

- Mitsuhiro AIDA

- U Rajendra ACHARYA

- Dmitri Aleks MOLODOV

- László PUSZTAI

- Yufeng ZHENG

- Gaochuang CAI

- Masahiko FURUTANI

- Hiroki MATSUO

- Zhongyue ZHANG

- Adam Karl SCHWARTZKOPFF

- Takashi ISHIDA

- Takumi HIGAKI

- Takahiro HOSONO

- Kei ISHIDA

- Makiko KOBAYASHI

- Ruda LEE

- Yuta NAKASHIMA

- Shin-Ichi OHIRA

- Atsushi SAINOKI

- Mitsuru SASAKI

- Keitaro TAKAHASHI

- Suttichai ASSABUMRUNGRAT

- Josep-Lluís BARONA-VILAR

- Nicorae BARSAN

- Jorge Norberto BELTRAMINI

- Olivier BOUTIN

- Paul BOWEN

- Pierre BREUL

- Maria Jose COCERO

- Patrice DELMAS

- Martin DIENWIEBEL

- Martino DI SERIO

- Derek ELSWORTH

- Carolina ESCOBAR

- Bruno FAVERY

- Etsuko FUJITA

- Tomonari FURUKAWA

- Jens HARTMANN

- Mohammad Abul HASNAT

- Yang JU

- Hoon KIM

- Ick Chan KWON

- Wen-Shing LEE

- Youn-Woo LEE

- Pavel LEJČEK

- Dongfang LIANG

- Bo LIU

- Tao LIU

- Hui LU

- Reiko ODA

- Yong Il PARK

- Shie-Ming PENG

- Christian RENTENBERGER

- Parasuraman SELVAM

- Amir SI LARBI

- Konstantinos Daniel TSAVDARIDIS

- Gioacchino (Cino) VIGGIANI

- Thomas WAITZ

- Yan XIAO

- Zhenghe XU

- Kazuki TAKASHIMA